At present, cast iron, cast aluminum and other casting parts are increasingly widely used. Since the risers, flash, burrs, etc. need to be removed during the actual processing of casting parts, the grinding process is particularly important. However, grinding and cleaning of castings is a very arduous task with poor working conditions (high temperature, dust, dirty environment) and high labor intensity. The traditional grinding process of casting parts mainly relies on manual grinding wheels, which not only has low grinding efficiency, but also cannot guarantee the quality requirements of parts.

The continuous increase in labor costs has increased the burden on foundry companies. At the same time, the dusty grinding environment has caused great harm to the health of workers. Occupational disease prevention and work injury compensation have further increased labor costs. The poor working environment and high labor intensity have also put companies in a difficult position to recruit workers. With the improvement of people's living standards and the enhancement of health awareness, it has become difficult for many foundries to recruit grinding workers. Therefore, in the foundry industry, especially in the casting grinding and cleaning process, it is a general trend to use robots to replace manual labor.

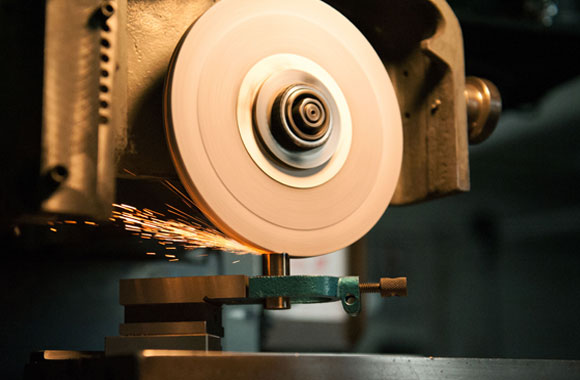

Diamond Grinding Wheel

Grinding inside and outside

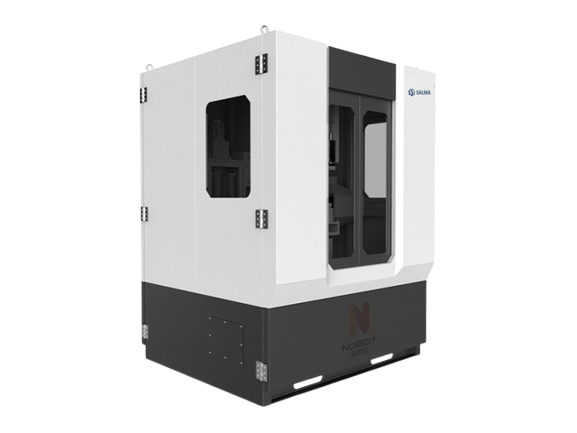

High rigidity

Small installation area; simple teaching and programming operation; stable performance and high production efficiency; excellent rigidity of the equipment, good mechanical mechanism can achieve extremely high efficiency to grind cast iron and steel products;

The equipment has excellent rigidity, and good mechanical mechanisms can achieve extremely high efficiency to grind cast iron and steel products;

Significantly improve the service life of consumables, reduce the cost of grinding a single piece, and improve grinding efficiency;

Each movement shaft is designed with positive pressure gas protection to prevent sanded dust from entering each shaft;

Improve the working environment

In order to solve the problems of grinding casting mouths and mold clamping joints in the casting industry, such as time-consuming and unstable product quality, this automatic grinding special robot equipment is specially designed. The machine is independently developed and effectively combines advanced mechanical design and control technology with the cost advantages of localized production, and flexibly tailors the polishing robots that suit different needs for customers.

Special robot for casting polishing

Casting grinding robot

Automatic Grinder For Foundries