Surface grinding is a very typical and common grinding process that is done in a CNC machine shop. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. Often, this process is used on workpieces requiring a high surface finish or precise dimension. In addition, it can be used to remove rust or dirt from the surface of equipment before fixing it or putting it back into service.

Surface grinding is widely performed in many industries, especially in general metalworking, industrial, and job shops. If you need to know this process further, this post is exactly for you. The article will help you get all the information about surface grinding, including its definition, how it works, advantages and disadvantages, applications, some tips, etc.

Surface Grinding Process: Before getting into the part of how surface grinding works, let’s first understand what you need in this process. Let us take a closer look at them.

Common workpiece materials cover cast iron and mild steel. While treated, these two materials are not prone to block the grinding wheel. Aluminum, stainless steel, brass, and some plastics are among the other materials. When grinding at high temperatures, the material weakens and becomes more prone to corrosion. This can also result in the loss of magnetism in applicable materials.

The abrasive wheel, the workholding device, and the reciprocating or rotary table are the three essential components of a surface grinding machine. In addition, grinding dressers are an essential part.

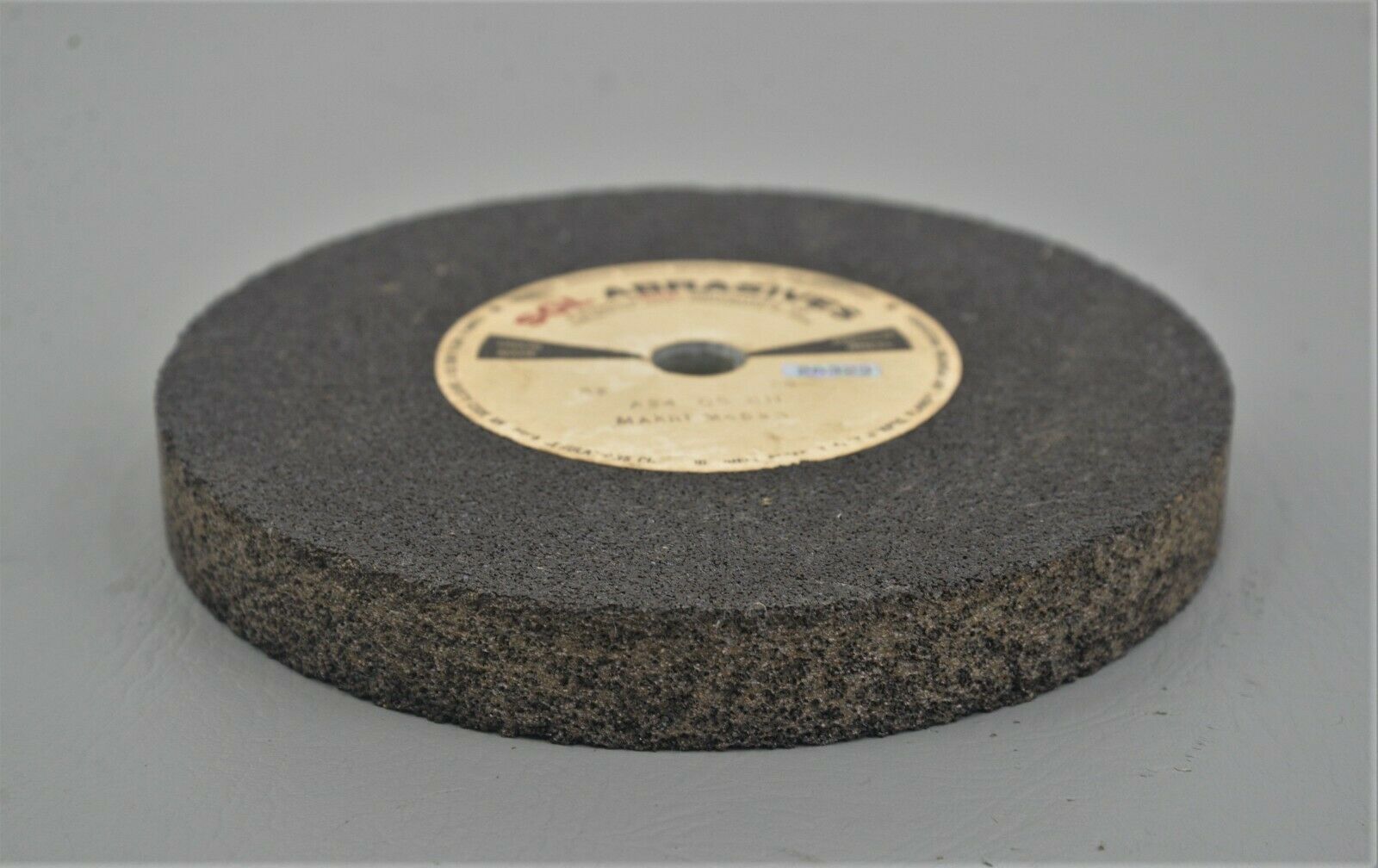

Abrasive Wheel: The abrasive wheel is used to smooth and refine the surface of a workpiece by eliminating surplus material. Aluminum oxide, silicon carbide, diamond, and cubic boron nitride (CBN) are four frequently employed as abrasive materials on the surfaces of grinding wheels. Among these materials, aluminum oxide is the prevailing choice. Diamond and cubic boron nitride (CBN) wheels possess exceptional hardness and can economically grind materials, like ceramics and carbides, which cannot be ground using aluminum oxide or silicon.

Diamond grinding wheel

High rigidity

Electric spindle

Workholding Device: The workholding device, also known as a chuck, holds the workpiece in position when it is processed. The chuck effectively secures the material in two distinct ways: ferromagnetic pieces are securely held in position using a magnetic chuck, and non-ferromagnetic and nonmetallic pieces are secured using either vacuum or mechanical means. If only a magnetic chuck is available, a machine vise (made from ferromagnetic steel or cast iron) put on the magnetic chuck can be employed for holding non-ferromagnetic workpieces.

Table: The table moves the workpiece around and across the face of the wheel as required to obtain the desired specifications.

Grinding Dressers: Grinding dressers are employed to preserve the condition of the wheel, and they can be either mounted on a table or placed on the wheel head for convenient application.

Occasionally, lubricants are applied to cool the workpiece and the wheel, lubricate the interface, and remove chips. It must be put directly into the cutting area to prevent the fluid from getting carried away by the grinding wheel. Typical lubricants encompass chemical fluids, water-soluble oils, synthetic oils, and petroleum-based oils.

The types of lubricants used for grinding usually depend on the type of workpiece material:

|

|

|

|

|

|

|

|

|

|

|

|

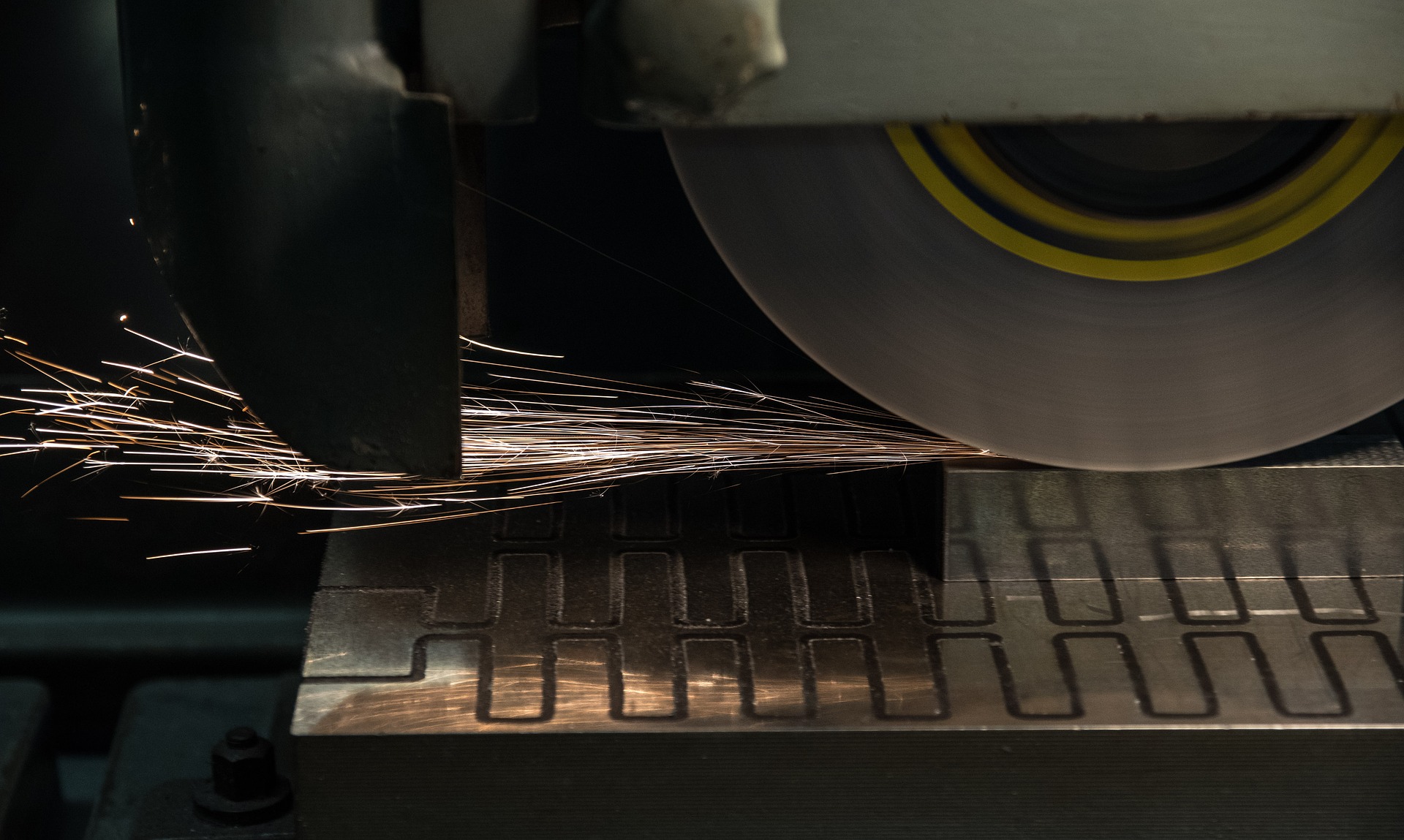

Surface grinding is a finishing technique that involves using a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to provide them a more refined appearance by removing the oxide layer and impurities on workpiece surfaces. This will also produce the necessary surface for functional uses.

First, the workpiece to be cut or smoothed is mounted onto a reciprocating table. In this step, a chuck is needed to keep the material in place. After the workpiece is secured to the reciprocating table, the machine slowly moves the surface of the workpiece across a grinding wheel that is spinning fast. As the grinding wheel spins, the reciprocating table carries the workpiece back and forth beneath its surface to remove surplus material until the required and even finish is obtained.

During the material removal process, excessive heat is produced, particularly when working with hard materials such as steel. This can impact the surface finish, so coolants are employed. This keeps the machining surface cool and carries the machined metallic particles away from the grinding surface to prevent surface abrasion.

Typically, surface grinders are classified into three types: horizontal-spindle grinders, disc grinders and double-disc grinders, and vertical-spindle grinders.

Vertical-spindle grinders are also known as wheel-face grinders. In this type of grinder, the face of a wheel is typically employed on a flat surface. Although a wheel-face grinder is widely utilized for quick material removal, some machines can perform high-precision work. The workpiece is secured onto a reciprocating table, which offers the flexibility to be adjusted according to the specific demands. Alternatively, it may be mounted on a rotary-table machine, allowing continuous or indexed rotation. Indexing enables loading and unloading at one station while grinding tasks are carried out at another. Typical components made using vertical-spindle grinders include stators, wafers, gears, rotors, stops and spacers, and inner rings and inner plates.

In horizontal-spindle surface grinders or peripheral surface grinders, the periphery (flat edge) of the wheel comes into contact with the workpiece to produce the flat surface. Generally, peripheral grinding works well in high-precision work on flat surfaces, tapers or angled surfaces, flat surfaces next to shoulders, and recessed surfaces. It is also suitable for slots and profiles. This type of surface grinder is utilized for grinding various components, such as pins, pistons, connecting rods, and bearing races.

Although disc grinding is similar to surface grinding, it has a larger contact area between the disc and the workpiece. Vertical and horizontal spindle types are both options for disc grinders. Double disc grinders can work on both sides of a workpiece at the same time. Disc grinders can achieve extremely tight tolerances. Typical components using these machines include rotors, gears, plates, spacers, and washers.

When close-tolerance dimensions and surface finishes are needed, surface grinding is often the go-to machining method. Similar to other processes, surface grinding has its advantages and disadvantages.

Surface grinding is a cost-effective and efficient manufacturing process for high-precision surfaces. Surface grinding offers several advantages, including:

|

Precise Surface Finishes: |

It achieves tight tolerances and smooth surface finishes by removing material in a controlled manner. |

|

Versatility: |

Surface grinding can be applied to various materials, including ferrous and non-ferrous metals, ceramics, and plastics. |

| Cost-Effectiveness: |

Surface grinding is a cost-effective solution for achieving high-quality surface finishes compared to other methods. |

|

Compatibility with Automation: |

Surface grinding machines can be integrated into automated production lines for increased productivity. |

|

Process Planning Programming |

We find the most optimized route and adjust equipment parameters, based on the tools and fixture designs to achieve optimized processing efficiency. |

|

Increased Durability: |

By removing surface irregularities, surface grinding improves the durability and longevity of components. |

|

No Skilled Operator Required: |

The task is simple and may be done manually or automatically. The machine does not require a highly skilled operator when run manually. |

However, it’s important to consider the disadvantages of surface grinding:

| Effects on Work Material Properties: |

The grinding process generates excessive heat during material removal, which can affect the surface finish if not properly controlled. |

| Produce Abrasive Swarf: |

The grinding process generates the abrasive swarf that must be properly contained. It is necessary to use coolants to carry the abrasive swarf away from the grinding surface to avoid scratching the surface. |

| Wear down Grinding Wheel: |

This process is not feasible to grind in the reverse direction. The nature of the task constantly wears down the grinding wheel and necessitates a considerable lot of spindle power. |

Surface grinding is an indispensable part of machining operations in various industries. Here are some key applications of surface grinding:

| Effects on Work Material Properties: |

The grinding process generates excessive heat during material removal, which can affect the surface finish if not properly controlled. |

| Smoothing and Finishing : |

The abrasive grinding wheel can remove small imperfections and improve surface finish. Surface grinding allows it to create smooth and polished finishes. |

| Producing Accurate Shapes and Profiles |

The grinding wheel can be dressed into different profiles to generate shapes on the workpiece. This allows the grinding of precision parts like gauges, cutting tools, mold cavities, and contoured surfaces. |

| Removing Stock and Squaring Blocks |

Surface grinders efficiently remove material from flat surfaces and can square up blocks and flats. This makes surface grinding a useful initial rough machining process before finer precision grinding. |

| Cleaning up Welds and Castings |

The abrasive wheel can remove burrs, weld seams, foundry defects, and flashes from castings. This provides a cleaned-up flat surface for subsequent processing. |

| Deburring Holes and Edges |

The edge of the grinding wheel can be used to add a radius onto edges or deburr holes. This eliminates sharp edges and improves safety. |

Many variables influence the surface grinding process and the quality of results obtained. Here are some key factors that affect the surface grinding process:

| Wheel Speed : |

Speed refers to the wheel RPM. Generally, the wheel RPM is usually constant in surface grinding. Note that Higher RPM allows faster material removal but can cause burn. Proper wheel speed depends on the material being ground. |

| Feed Rate : |

The traverse rate of the workpiece into the wheel. Faster feeds increase material removal rates but can cause chatter marks. Slower feeds produce finer finishes. |

| Producing Accurate Shapes and Profiles |

The grinding wheel can be dressed into different profiles to generate shapes on the workpiece. This allows the grinding of precision parts like gauges, cutting tools, mold cavities, and contoured surfaces. |

| Depth of Cut |

Deeper cuts allow more material removal per pass but can cause wheel wear, chatter, and burn marks. Lighter cuts are better for finishing operations. |

| Wheel Type |

Depending on the hardness of the metal being ground and removed, wheels ranging from aluminum oxide and silicon carbide to diamond and CBN are used to remove material. Other specialized wheels, such as cork, are available, but these are intended for burnishing and polishing rather than material removal. |

| Wheel Dressing |

Improper dressing can lead to glazing, rapid wheel wear, vibration, and a poor finish. The right dressing schedule maximizes cutting action.

|

| Coolant Usage |

Grinding fluids cool the workpiece and wheel, flush away chips, and prevent wheel loading. The proper type, flow rate, and filtration should be used.

|

| Operator Skill |

An experienced operator will select proper parameters and ensure quality results. Understanding the interplay of the factors is important.

|

| Wheel Dressing |

Improper dressing can lead to glazing, rapid wheel wear, vibration, and a poor finish. The right dressing schedule maximizes cutting action.

|

Safety is paramount when engaging in surface grinding. Follow these essential precautions:

To achieve optimal results in surface grinding, consider the following tips: